Working

Roll Forming

The “Three-Roll Type Bending Roll” literally curves a plate in between three rolls by pressing the upper roll. Temporarily welding for finishing.

Setting a steel plate between three rolls

Setting a steel plate between three rolls  Entering a value in the bender control panel

Entering a value in the bender control panel  Gradually decreasing the diameter

Gradually decreasing the diameter  Checking the dimension

Checking the dimension  Temporarily welding

Temporarily welding  Finished

Finished Bending

Bending is worked using a press.

A bending die is used.

A bending die is used.  Giving pressure on the steel plate

Giving pressure on the steel plate  Finished

Finished Combination Bending

To use a press, a die is required for bending the material.

Bend at a certain position of the flat plate. A die is required for bending.

Bend at a certain position of the flat plate. A die is required for bending.  Next, bend at another position as if drawing a circle. An R-forming die is required.

Next, bend at another position as if drawing a circle. An R-forming die is required.  Gradually decreasing the diameter. A part is finished by bending a single steel plate multiple times like bending at two positions, three positions.

Gradually decreasing the diameter. A part is finished by bending a single steel plate multiple times like bending at two positions, three positions. Roll Forming of Various Section Steels

Bending of round pipes, square pipes, flat bars, angles, H-section steels, I-section steels, and beams.

Other types of section steels are bent. Please feel free to contact us for any question.

Setting a round pipe on the bender

Setting a round pipe on the bender  Entering a value in the bender control panel

Entering a value in the bender control panel  The round pipe will be bent by feeding it through the driven three rolls.

The round pipe will be bent by feeding it through the driven three rolls.  Gradually decreasing the diameter

Gradually decreasing the diameter  Check the dimensions

Check the dimensions  Finished

Finished Draw Bending

The “Draw Bending” refers to the cold bending process of pipes. This is a working technology to form a straight (round, square, etc.) pipe into a designated bending radius and angle.

Setting a requested die

Setting a requested die  Inserting a mandrel for prevention of ovaling

Inserting a mandrel for prevention of ovaling  Inserting a mandrel for prevention of ovaling

Inserting a mandrel for prevention of ovaling  Rotating the die

Rotating the die  Releasing the chuck and checking the dimensions

Releasing the chuck and checking the dimensions  Finished

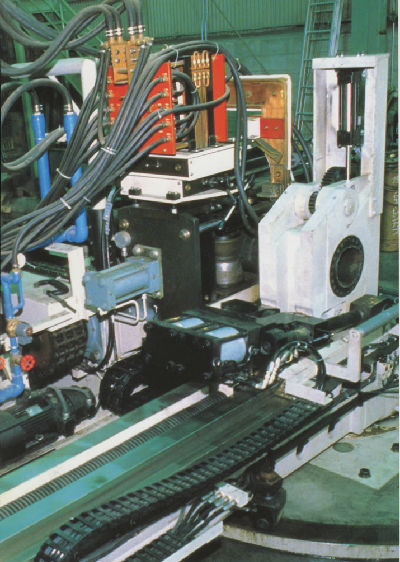

Finished Induction Bender

We can bend the steel according to your required dimensions without manufacturing a die. In terms of the ovalization factor and thinning factor, induction bender is more excellent than cold bending.

Applicable Steel Materials

Metals such as steel, stainless steel, aluminum, copper, titanium, brass, nickel, and non-ferrous metals